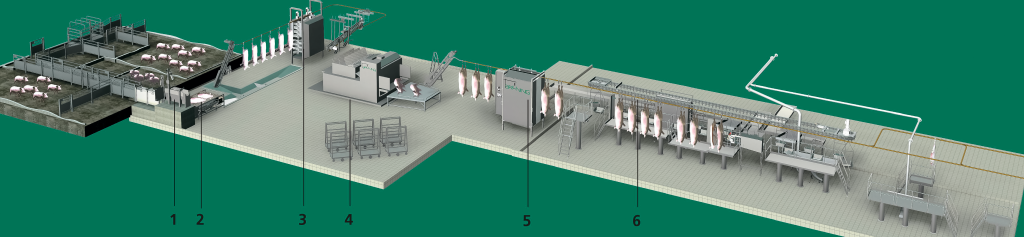

Pig slaughter lines

Exsanguination

We supply components such as conveyor belts, elevators, blood collection and processing devices. This equipment ensures efficient exsanguination of animals and reduces the risk of contamination to a minimum.

Pre-washing

To improve the efficiency of the scalding process, carcasses are pre-cleaned with washing machines.

Scalding and dehairing

The result of scalding and dehairing depends primarily on the chosen scalding method and dehairing machine.

The final result also depends on such parameters as:

- scalding time,

- water temperature,

- season,

- pig breed.

We offer equipment optimally suited to any slaughter capacity.

Additional cleaning

Machines such as singeing furnace, polishing machine and brush washing machine provide

high quality and hygiene of carcasses.

We offer a wide range of equipment for this.

Carcass cutting line

Our company offers various concepts for ergonomic and efficient equipping of workstations and veterinary control posts.

To do this, we supply various versions of equipment for the extraction of abdominal and thoracic organs, sawing carcasses, finishing and veterinary control, transportation of slaughter by-products, lifting platforms.

Cooling, deboning and shipping

For these areas, we offer various conveyor systems and equipment tailored to the individual requirements of the client