Utilization of slaughterhouse waste

We offer complex solutions for:

- Utilization – processing of waste of animal origin, fallen livestock and production of meat and bone meal and animal fats

- Fishmeal and fish oil production – processing fish waste and whole fish to produce high quality fishmeal and fish oil

Vorteile der Verwendung unserer Technologien

- Problems with utilization are solved

- Valuable protein is produced

- The cost of importing protein meal is minimized

- A high quality product with a market value is produced

Competence & know-how

- Many years of experience in well-established good relationships with customers have made us a professional partner

- Modern production is always close to the consumer

- High competence in development, design, project management, production and installation

Products and services

- The equipment of our partners is offered individually and is manufactured according to the needs of the customer. We can supply everything from a single machine to a turnkey plant.

- It is very important for us that the efficiency and reliability of our equipment contributes to the profitability and sustainability of our customers’ business.

- The main spare and wear parts are always available in our warehouses

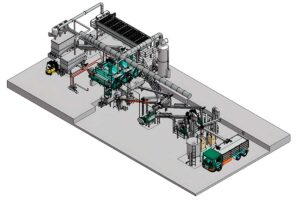

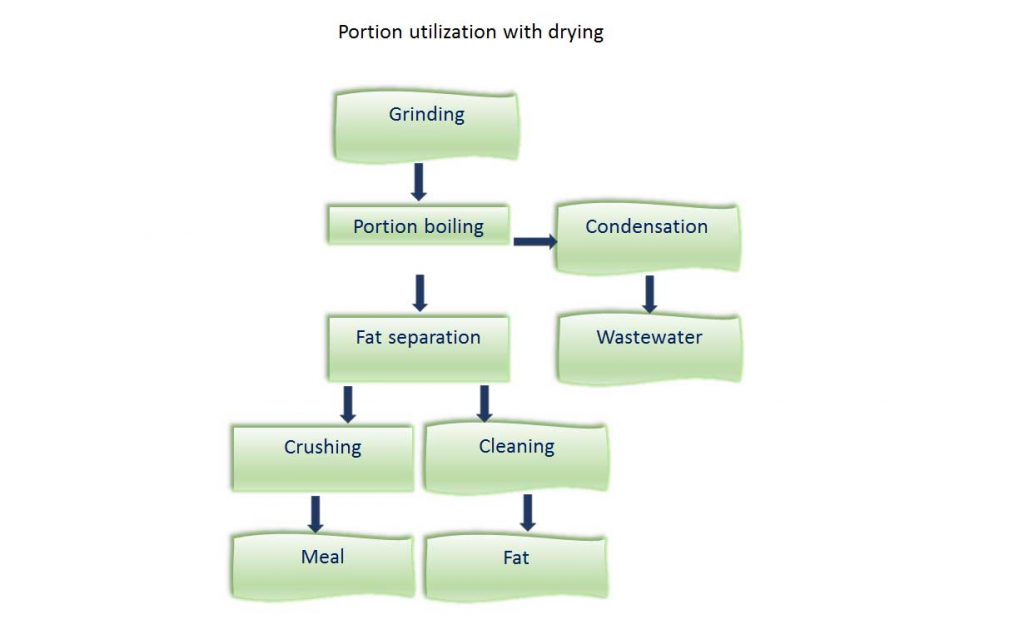

Batch utilization with drying

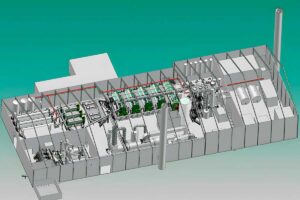

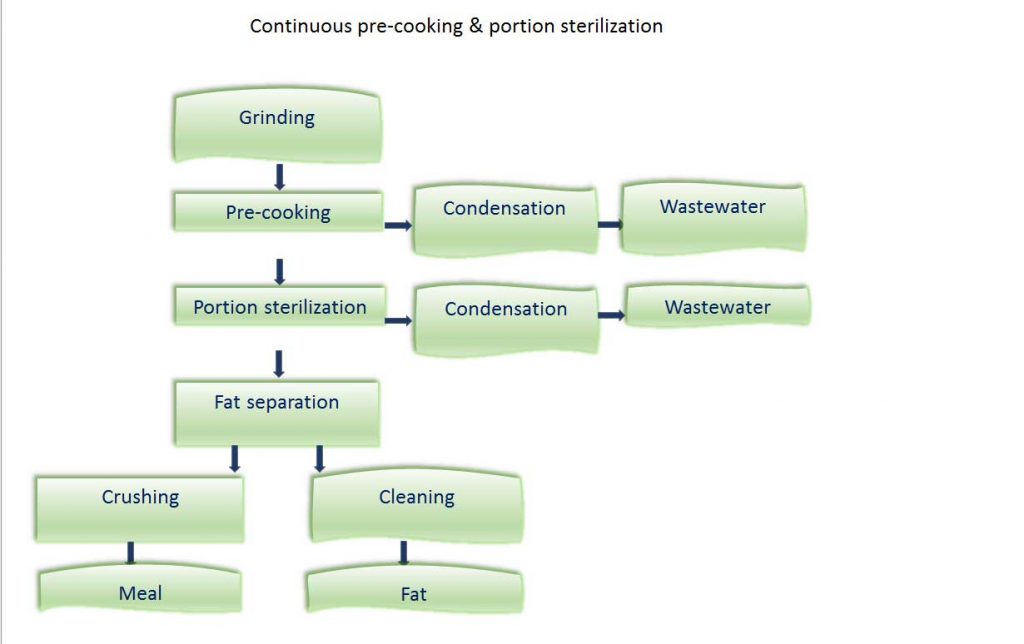

Continuous pre-cooking and portion sterilization

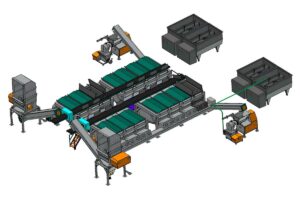

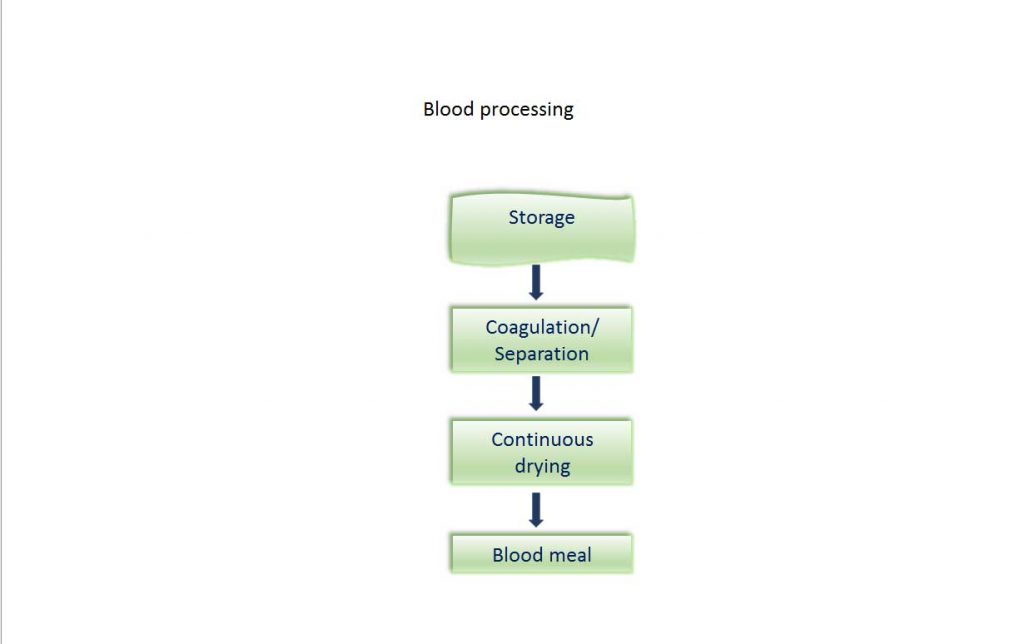

Blood processing

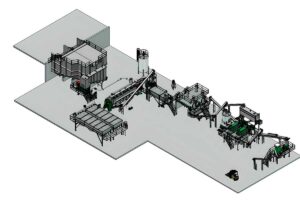

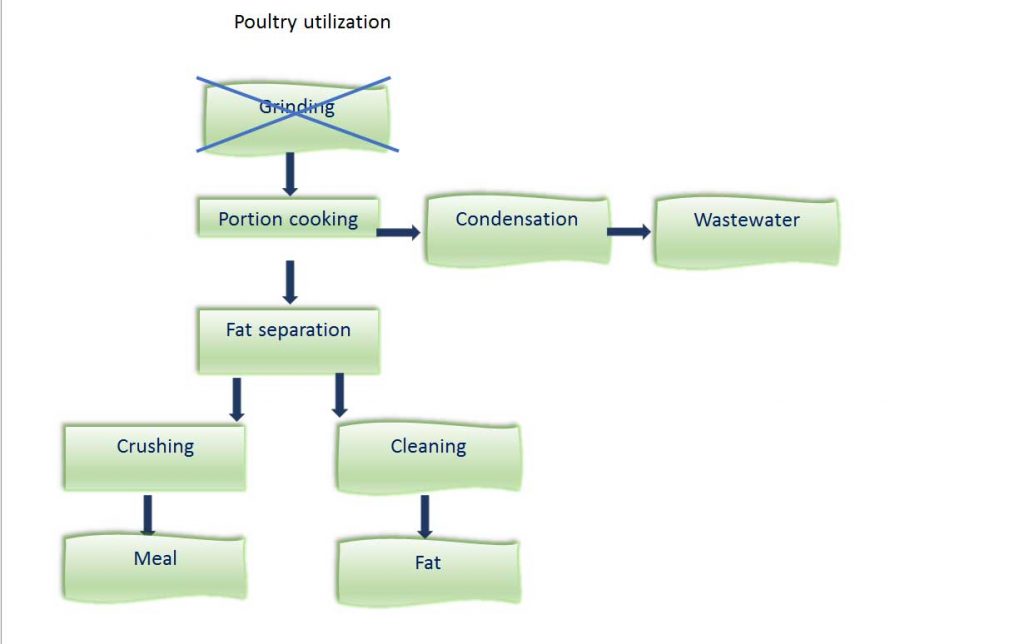

Utilization of slaughterhouse poultry waste

Example: Slaughter 6000 pcs/h, 2 kg live weight, 8 h/d

Raw materials for utilization: from 6000 broilers/hour (8 hours shift), live weight: 2 kg.

| Blood: | 2.900 kg/d |

| Feather (wet): | 11.500 kg/d |

| Meat waste from poultry slaughter: | 14.400 kg/d |

| Mortality (assume 2%): | 2.000 kg/d |

| Hatchery waste (estimated): | 1.000 kg/d |

| Sludge (effluent treatment) (not justified) | – kg/d |

| Total | 31.800 kg/d |

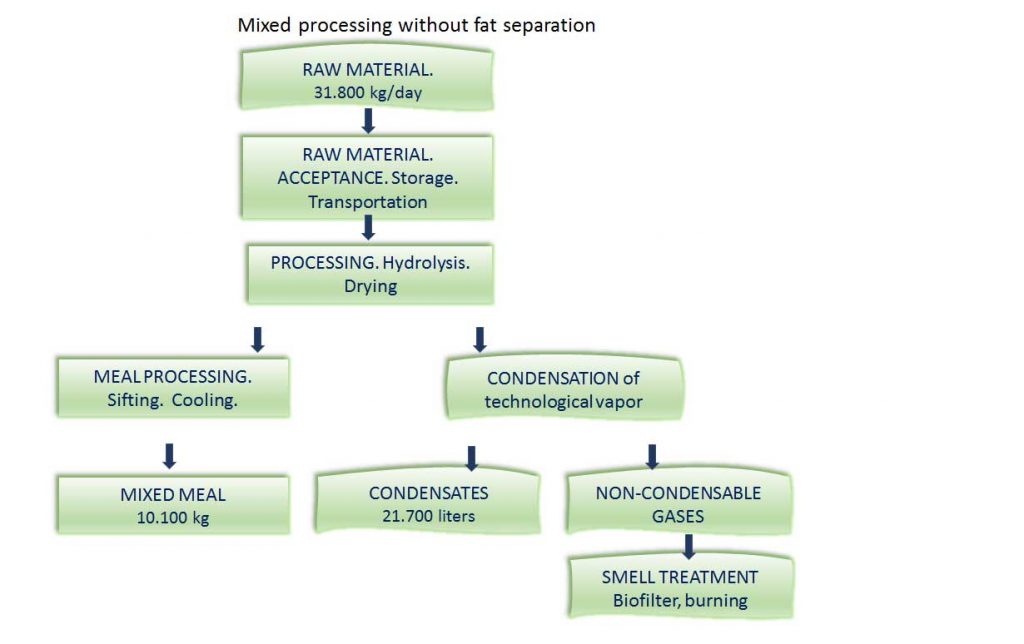

Mixed processing

Without fat separation:

A mixture of all raw materials.

Final product:

- mixed meal with a fat content of 18-25%

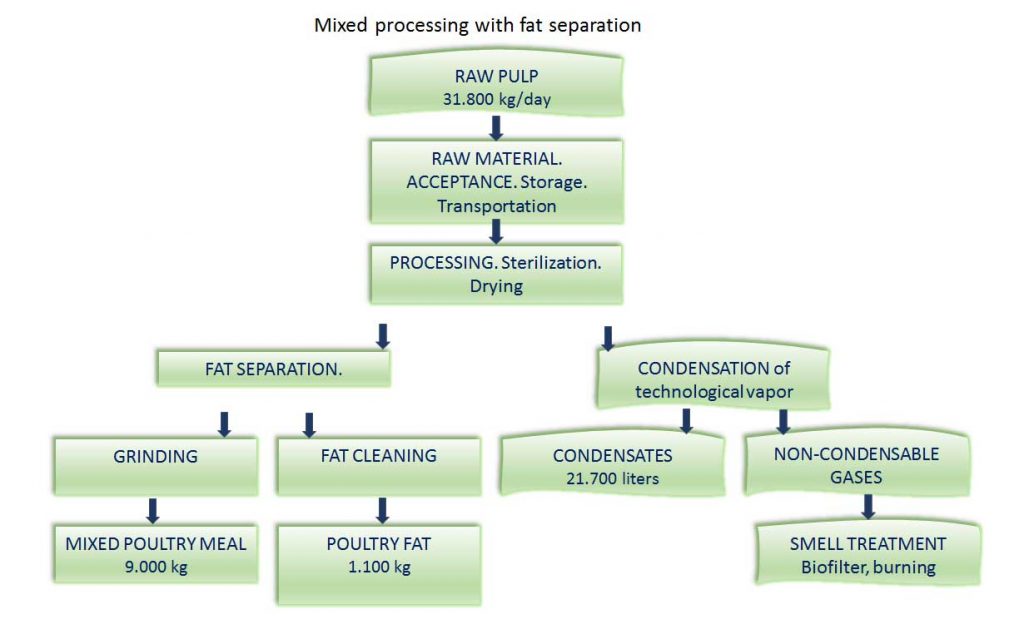

Mixed processing with fat separation

With fat separation:

A mixture of all raw materials.

Final product:

- Mixed poultry meal with a fat content of 10-15%

- Bird fat

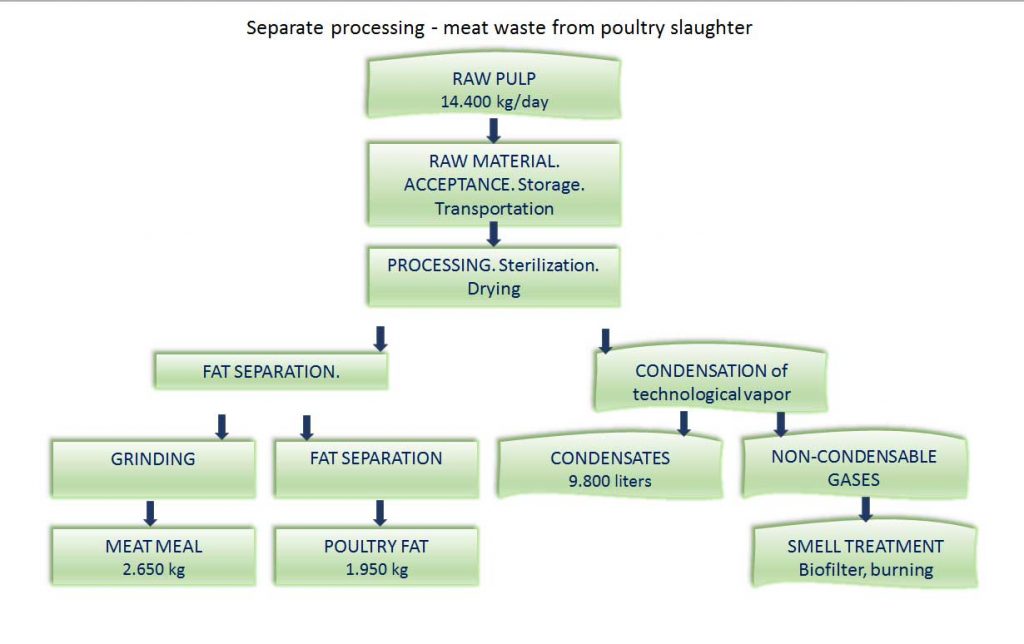

Separate processing of meat waste from poultry slaughter

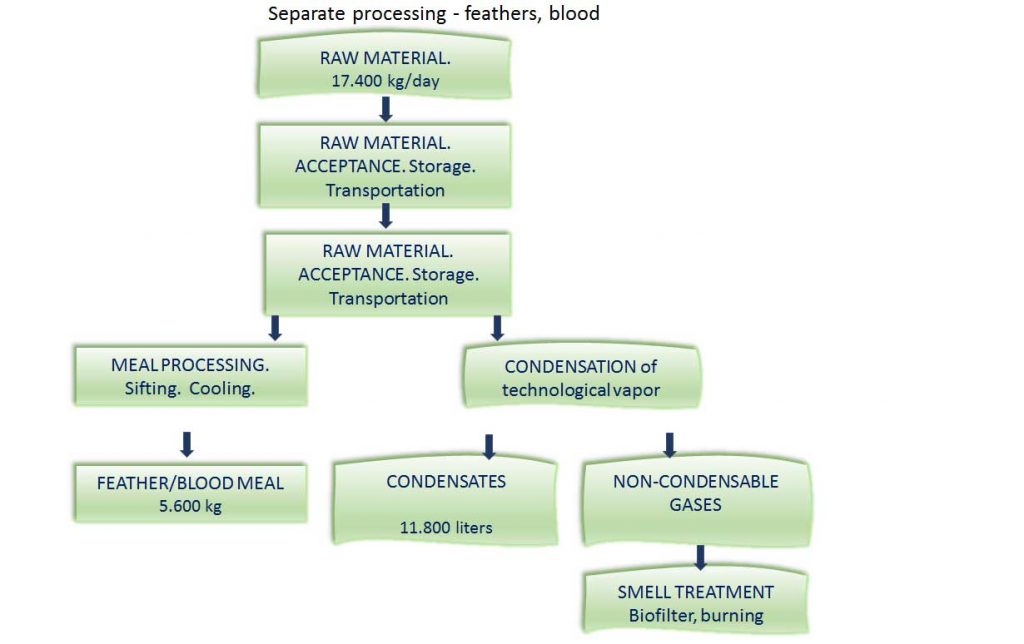

Separate feather/blood processing

Raw materials are processed separately

Final product:

Feather / blood meal

Poultry meat meal with a fat content of 10-15%

bird fat

Final product (typical analysis)

Meal from mixed poultry waste

Protein: 68%

Humidity: 6%

Fat: 20%

Fiber: 1%

Ash: 4%

Protein digestibility: 85%

Lysine: 2.3%

Cystine: 1.5%

Methionine: 0.7%

Meal from poultry meat waste

Protein: 66%

Humidity: 5%

Fat: 12%

Ash: 11%

Calcium: 4%

Phosphorus: 2%

Protein digestibility: 90%

Lysine: 3.7%

Cystine: 0.7%

Methionine: 1.2%

Meal from feathers and blood

Protein: 85% Protein: 85%

Humidity: 6%

Fat: 7%

Protein digestibility: 80%

Lysine: 3.5%

Cystine: 1.2%

Methionine: 0.3%

Production of fishmeal and fish oil

Fish meal and fish oil.

Range of equipment:

- Choppers

- Kettles

- Presses

- Dryers

- Evaporation lines

- Condenser

- Meal processing equipment

Manufacture of pet food

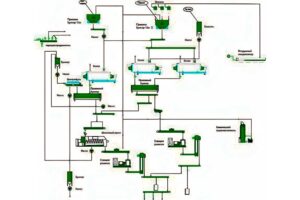

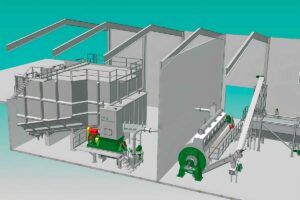

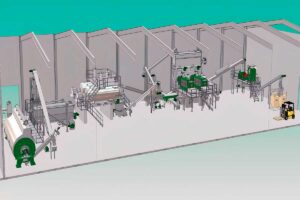

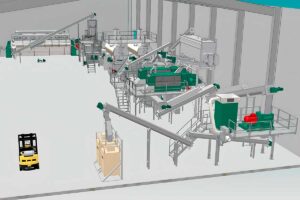

Photos of our facilities

- Reception of raw materials

- Technological equipment

- Fat removal

- Meal processing

- Condensation system

- Smell cleaning

- Transportation from the slaughter line

- Storage.

- Storage bin for:

- feather

- mortality

- pulp material

- Capacity for:

- blood

- Storage bin for:

- System for filling technological equipment

- Metal detector

- Crusher

- Portion kettle

- Pre-cooking, drying

- Sterilization

- Screw press

- Fat removal

- Removal of fat, cooling of meal

- Vibrating sieve (sifting)

- Cooling

- Grinding

- Filling in bags

- Air cooled condenser

- Water cooled condenser

- Cooling tower

Process air and indoor air

Cleaning in

- biofilter

- chemical cyclone (gas cleaner)

Extract from the premises

Cleaning in

- biofilter

- carbon filter

- chemical cyclone (gas cleaner)

Process air

Burning in

- steam kettle

- incinerator